Chlorine Dioxide Producing Equipment

International Dioxcide is the industry leader in chlorine dioxide (ClO2) generator fabrication. Every aspect of the equipment process from design, engineering, manufacturing, and installation, focuses on following strict safety standards. Chlorine dioxide is unstable and cannot be compressed and stored like chlorine, because it readily decomposes. In most biocidal applications for both small and large-scale applications, it is prepared on-site, typically using one of two methods: “generation” and “activation.”

International Dioxcide can help ensure success with specific chlorine dioxide equipment requirements.

Methods of Generation

Over the past 70 years of commercial ClO2 use, several approaches to generate ClO2 on-site have been developed. The majority of ClO2 used for disinfection, sanitization and selective oxidation purposes is produced by reacting NaClO2 with a source of hypochlorous acid (HOCl). In this process called generation, NaClO2 is safely converted to ClO2 in dilute aqueous solutions.

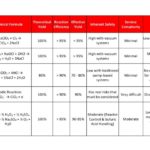

The most common high purity ClO2 generation chemistry reacts liquid sodium chlorite with gaseous chlorine or hydrochloric acid (HCl). Typical ClO2 generation reaction chemistries found in the marketplace are shown in Table 4.

Chlorine Dioxide Equipment

On-site generation of ClO2 using either two or three-chemical precursors is essentially a self-contained ClO2 production plant installed at the point of application. When choosing ClO2 generation equipment, it is important to not only ensure that the company selling the equipment has the technical capabilities needed to support the technology, but to also consider the safety and reliability of the equipment.

The ClO2 business of International Dioxcide have been engineering, fabricating, installing and maintaining ClO2 generators for over 40 years. and has over 1,000 units installed worldwide. All systems are engineered for simplicity and reliability and designed to meet the highest safety and purity standards. Every aspect of the equipment process, from design, engineering, manufacturing, and installation are done in-house, with a strong, focus on following strict safety standards. With over 1000 installations around the world, the business has extensive experience to meet your unique ClO2 requirements. As a complete ClO2 solution provider, we can respond quickly to resolve any issues, saving your company valuable time and money.

ADOX™ Generation Equipment

The ADOX™ brand of chlorine dioxide generators by International Dioxcide offers a series of generator platforms to satisfy a wide range of ClO2 applications. Additional design elements include precursor chemical storage, distribution, dosing control, and monitoring that will safely and economically meet your site-specific chlorine dioxide needs (see Table 5).

ADOX™ InLine Generator Platform

The ADOX™ InLine generator is the newest vacuum-based generation platform for cost effective and simple chlorine dioxide generation technology when using three chemical chlorine dioxide reaction chemistry (chlorite, bleach and acid). The ADOX™ InLine generator produces chlorine dioxide in an inherently safer process than competitive offerings. The design uses an eductor that ensures precursor chemical flows only when there is sufficient dilution water flow to produce vacuum in the educator and eliminates the need for any chemical pumps that are undesired with chlorite chemistry. Once water flow is established, 25% or 31% NaClO2 solution is educted into a dilution water stream, where it is combined with sodium hypochlorite (bleach) and hydrochloric acid to produce ClO2 solution.